At this year's annual symnposium of the American Rock Mechanics Association (ARMA), one of six "Best Paper" awards went to "A Microscale Analysis of Millimeter-wave Induced Vitrified Basalt for Use in Enhanced Geothermal Energy Systems," by recent ERL/CEE alum Dr. Eve Meltzer, CEE Research Scientist Damian Stefaniuk, and ERL/CEE Prof. Herbert Einstein.

http://dspace.mit.edu/handle/1721.1/153727

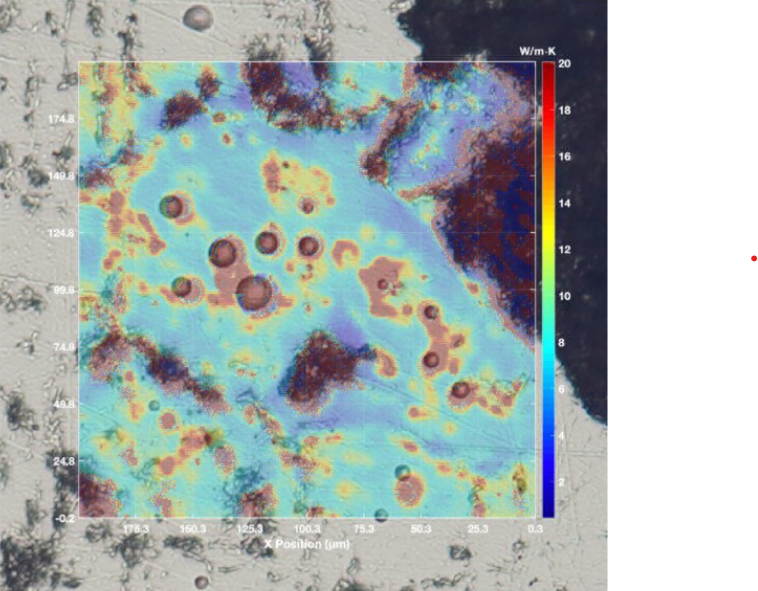

"Extraction of the energy available from geothermal heating in the Earth could provide substantial contributions to energy needs long-term. However, there are major technical limitations with the current geothermal drilling process. A new technology in the field of EGS that uses a millimeter (MM) wave gyrotron, which allows for quicker, more efficient drilling could be a potential solution to these limitations. The MM-wave drilling process, a technique developed by Dr. Paul Woskov of the MIT Plasma Lab, has two significant advantages as compared to traditional drilling: 1. The well hole advance is through melting of the rock, which is faster than mechanical drilling. 2. The molten rock then solidifies, creating a vitrified wall support without the need for extra casings. This drilling and casing process can potentially save money, time, and material. The study presented in this thesis is aimed at understanding the strength and microscale mechanical and chemical properties of the vitrified material to see what is happening to the rock, specifically Basalt, pre- and post-melting by using a series of experimental and analytical tools. These include: Scanning Electron Microscopy (SEM), Electron Dispersive Spectroscopy (EDS), Nano-Indentation, Raman Spectroscopy, and optical imagery. The results presented in this thesis show the creation of a non-crystalline amorphous solid that has relatively high strength values with slight evidence of micro-cracking. There are significant elemental differences between the basalt matrix, transition zone matrix, and solidified melt in addition to changes in the molecular phases. The partial melting of basalt minerals throughout the transition zone was also recorded. Ultimately, due to micro-cracking and the variability in the transition zone's chemical make-up, there may be significant risks to using this material as a well-bore casing as it is now. However, these results open up the possibly of future research in the field of environmental sustainability for alternative uses of this new vitrified material."